Project description

The EENSULATE project is a research project funded by the European

Commission under the Horizon 2020 programme. It gathers 13 partners from eight different European countries.

EENSULATE approach

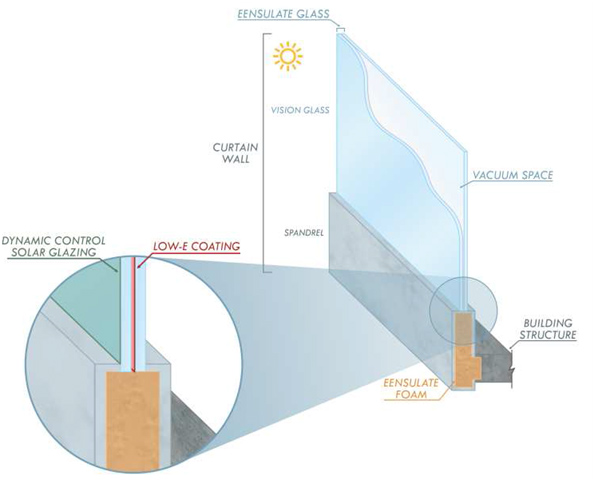

The EENSULATE project has designed innovative lightweight (with 35% weight reduction compared to the currently best-performing modules), highly insulating energy-efficient components. Simultaneously, associated enabling materials for cost-effective retrofitting and new construction of curtain wall façades were developed.

EENSULATE represents an ambitious project, which aimed to introduce a novel unitised curtain wall system capable of meeting the market demand. The goal was an affordable (28% reduction of total refurbishment costs), high-performance prefabricated façade retrofitting solution with reduced weight and thickness. The project’s objective was to help bring existing curtain wall buildings to ‘nearly zero energy’ standard and to reduce energy bills by at least 20% while complying with the structural limits of the original building structure and national building codes.

Eensulate draws a strategy for sustainability of curtain walls by leveraging on:

- High durability (maximum service life) of the enabling materials and overall component

- Good thermal breaks between the curtain wall and the sub-structure through the innovative spray foam

- High R-value due to the Vacuum Glass as those achievable with triple glazing systems but with lower weight and less material use.

- Low-temperature manufacturing process for the vacuum glass allows the use of low-E and spectrally selective glass coatings, which can significantly reduce energy loads and improve comfort close to the wall

Market Demand & Expected Impacts

- Improvement by at least 25% of the insulation properties

- Reduction by at least 20% of the total costs

- Improvement by at least 20 % of durability

- At least a 15% reduction of the energy spent during the whole life cycle of a building

- Easier implementation

Environmental, social and regulatory drivers

- Respect for sustainability principles

- Improvement in indoor air quality

- Contribution to standardization and certification activities

The performance of the EEENSULATE solution was assessed at full scale prototype. Demonstration buildings are located in two different climates (Italy and Poland). The focus was placed on the thermo-acoustic behaviour of the demo buildings,indoor comfort and different parameters were monitored:

- Weather data

- Internal and external wall temperature

- Heat flux

- Indoor temperature and humidity

- Sound transmission loss

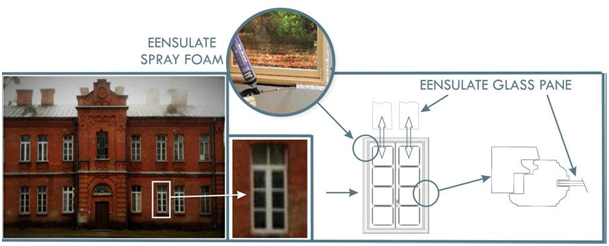

Three different demo buildings addressing curtain-wall constructions and historical buildings were used for validation of results:

Public Library San Giovanni

(Pesaro, Italy)

City Museum

(Dzierżoniów, Poland)

EENSULATE Objectives & Technologies

Main objectives

- Characterize and understand how the Eensulate components work in real conditions considering the dynamic and thermos-tuneable characteristics of the glass coating, developing accelerated testing procedures based on UV radiation, temperature, moisture, and soiling factors.

- Develop quality control procedures enabled by sensors and industrial measuring techniques.

- Develop durability testing procedures at material and component scale integrating results from accelerated testing of the different enabling material innovations.

- Prepare a testing procedure for the materials and components to comply with major regulations and standards including fire resistance.

- Validate in different demo buildings located in two different climates (Italy and Poland) the performance of the curtain wall and fenestration products by means of a monitoring system based on sensors embedded onto the glazed components, designed for the evaluation of the room thermo-hygrometric, lighting, acoustic and air quality.

- Develop design, installation, and operational guidelines.

- Develop product development and scale-up roadmap with associated financial plans leveraging on current manufacturing assets by the partners as well as an extended network of licensed parties across the EU and beyond.

- Validate the environmental and resources sustainability for the Eensulate product family, preliminary evaluation of the impacts through LCA approach, according to ISO 14040/14044 standards

- Quantify the benefits for users (ROI, reduced bills, etc.)

- Develop a commercialization Strategy and associated Business Plan with potential economic benefits assuming mature market costs.

Main technologies

The EENSULATE project designed a curtain wall module that consists of two main insulating parts:

EENSULATE FOAM

Highly insulating and environmentally friendly material used to produce a mono-component (OCF) and bi-component (TCF) foam. The TCF allows for the cost-effective automated manufacturing and insulation of the opaque part of the curtain wall module. The OCF enables a significant reduction of thermal bridging during the installation process.

EENSULATE Vacuum insulated glass (VIG)

Lightweight and thin double pane vacuum insulated glass (VIG) with innovative sealant and getter technologies and manufactured through an innovative low-temperature process, enabling the use of fully toughened glass. The VIG guarantees the insulation of the transparent part of curtain walls.

The VIG is manufactured using a tailored process that implements innovative sealant and getter strips, ensuring the achievement of the target performance. The VIG is manufactured in two sizes:

• small-scale VIG prototypes (500x500 mm)

• large-scale VIG prototypes (1000x1000 mm)